Custom 3D Printed Cage Successfully Treats Infected Tibial Shaft

A recent case report published in Cureus journal highlighted the use of a novel 3D-printed titanium mesh cage to treat an infected tibial shaft ‘non-union’, a medical term for fractures that take an extended period of time to heal. This report describes the successful treatment of a 25 year-old woman who suffered from a nonunion fracture for more than a year. Non-union fractures are usually treated by removing infected tissue and bone grafts. This can be a difficult process. However, a 3D-printed titanium mesh cage was used in her case, providing a more customized and effective solution for the patient’s fracture.

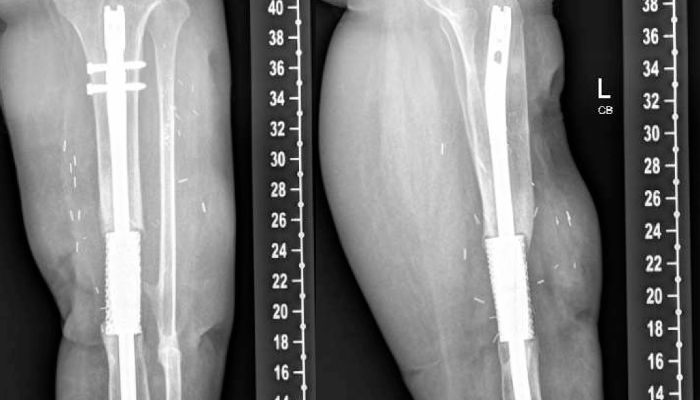

CT imaging of the patient’s leg was used to render 3D images, ensuring that the cage, which was designed and manufactured in collaboration with Restor3D Inc, fit the exact dimensions of the patient’s tibial shaft. The implant was placed in the bone defect during surgery. Next, an intramedullary needle was inserted through the 3D printed titanium mesh cage. The screws secured it in place. Multiple perforations were used to improve blood flow and encourage bone growth. Titanium material was selected for its strength, biocompatibility and durability.

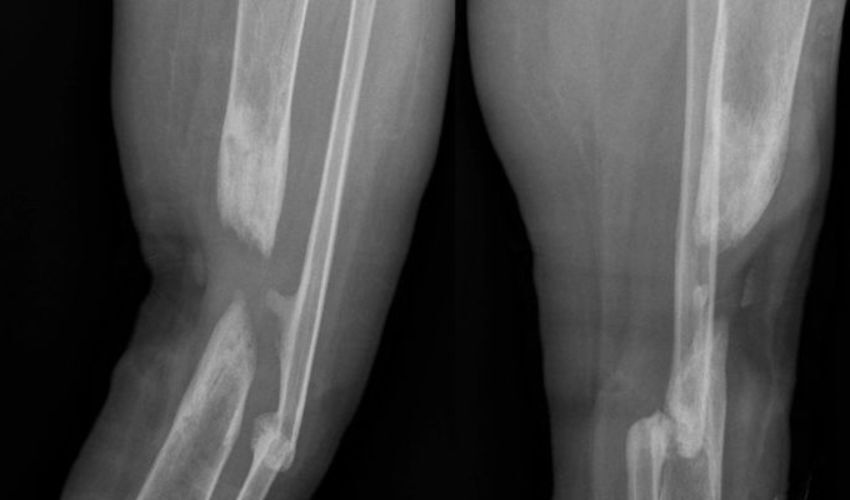

Pre-op Xray of a patient with a Tibial Shaft fracture in her left leg (photo credit: Cureus Journal).

The patient saw a dramatic reduction in pain and inflammation as well as increased mobility. The patient experienced bone regeneration and complete fusion of his non-union site. Follow-up scans confirmed this. The titanium mesh allowed for better visualization during the healing process, allowing for closer monitoring of the patient’s progress. After the surgery, the patient was able to bear weight and resume daily activities one year later.

The Potential of 3D-Printed Implants

Patients-specific 3D-printed titanium implants are a great option for complex cases with severe bone defects. Although this technique isn’t yet widespread, it can be done with care.The case illustrates the potential of 3D-printed technology in medicine. By using CAD software to design custom-made implants, doctors can create implants that are perfectly suited to the patient’s anatomy. This can increase the success rate and decrease the chance of complications.

A scan of the patient’s leg one year after treatment. 3D Printed titanium mesh cage, intramedullary nail and screws.

Additionally, 3D printing technology makes it possible to create complex parts that would not be possible using traditional manufacturing techniques. Implants can have features that promote bone growth and healing. This is the case with this biocompatible coating for the titanium mesh cage. Learn more about the role of the implant 3D printed in this treatment here.

What do you think of 3D printed orthopaedic implants? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo Credits: Cureus Journal