Researchers use low-cost 3D printer to develop new method for creating microspheres

For high economic benefits, researchers make uniform polymer microsphere materials using powerful microchannel droplet generation equipment. These microspheres can be used for many purposes, including in medical devices, biotechnology and the construction industry.

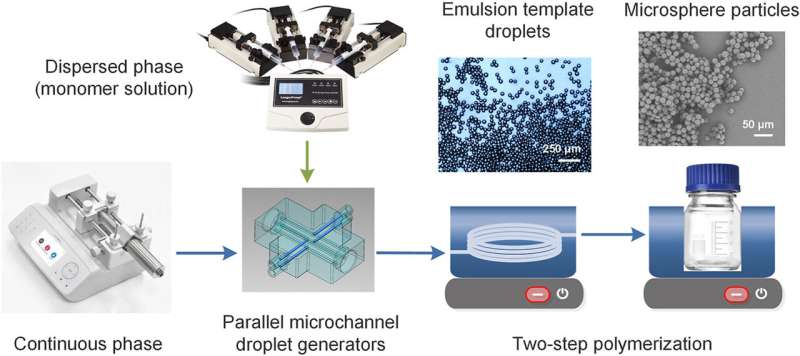

A group of researchers have created a novel way to create high-throughput microchannel dropslet generation equipment. It is easy to realize using commercially affordable 3D printing and reduces the number integrating droplet generators.

The journal publishes their findings. Particuology October 22,

The prototype was built using a low-cost 3D printing method. It only required four parallel droplet generators. The prototype device was as powerful as a microchannel device with hundreds of parallel droplet generators. The advanced microchannel droplet generation equipment was developed by the team. They also created a two step emulsion template polymerization method that converts droplets to solid particles.

The new device, which was developed by the team, works better than traditional microfluidic devices. The capillary-assembled, stepwise microchannel is unique because it can withstand the flow rate variation in the continuous phase as well as the fabrication error in its microchannel structure. It produced droplets with a very high frequency when it was operated under the jetting flow conditions,” Kai Wang, associate professor at Tsinghua University, said.

The four-channel capillary-assembled stepwise microchannel droplet generation equipment the team fabricated can contribute 2.8×104 Droplet generation frequency at Hz of ten microns. This quantity would have been possible with conventional parallel-scaling microchannel devices that work with dripping flow.

Guangsheng Liu, a professor at Tsinghua University, stated that the “core scientific discovery of our research is the understanding the flow rate, fabrication error robustness, and capillary-assembled micro-channel in jetting flows, which greatly reduces the difficulties in fabrication, and operation of these microchannel devices.”

Methods of creating uniform droplets or particles using microchannel devices are difficult and costly. Because of the limited amount of particles produced by a single microfluidic driplet generator, it is difficult to scale up production to increase its speed. This has prompted continued research into more efficient microfluidic driplet generator methods.

The team was able to create complex microchannel structures using 3D-print technology without having to use complicated layer sealing procedures. Their device was used to produce droplets of average size 32-52mm with variation coefficients ranging from 4.5 to 8.4 percent. They used their microfluidic platform to polymerize the droplets and make solid particles.

These microsphere materials are of great economic value. They have many applications, including the spacers for liquid crystal displays and the standard particles to calibrate particle size analyzers. For microencapsulation or drug delivery, microsphere particles can be used with high dispersibility in medicine. There are many types of materials that make microspheres. The important polymer particle can be easily prepared using monomer polymerization or cross-linking technologies.

The team is looking ahead to future research and plans to scale up the stepwise capillary-assembled microchannel device with more droplet generation units and a more precise controlled method, which is based on deep learning droplet image recognition. Kai Wang stated that it was important to encourage the industrialization and distribution of particle preparation technology in order to reach the international market for uniform microsphere materials.

Additional information:

Shenglong Zhang et. al. High-throughput production of uniform droplets by parallel microchannel generators and the preparation polystyrene macrosphere material. Particuology (2022). DOI: 10.1016/j.partic.2022.10.010

Citation:

Researchers develop new methods to create microspheres using a low-cost 3D printer (2022, November 22).

Retrieved 22 Nov 2022

from https://phys.org/news/2022-11-low-cost-3d-printer-method-microspheres.html

This document is subject copyright. Except for fair dealings for private study or research purposes, there is no

Without permission, part of the content may be reproduced. The information is provided only for informational purposes.