New proteins to revolutionize gluten-free baked goods

Gluten is the most abundant natural protein and it has many fantastic properties. For example, it keeps a well cooked dough airy until baking stabilizes its open-pored structure. Prof. Mario Jekle of the University of Hohenheim Stuttgart works on a process in which certain proteins, like those from maize, peas or rapeseed can be used to replace gluten or linked together in chains that have gluten-like properties. Saponins from daisies and quinoa seeds or mucilages from cereal hulls additionally support the formation of an airy dough—and in some cases enrich it with valuable dietary fiber. The result can be put in the oven—or printed out in the 3D printer in an energy-saving way and with many additional options.

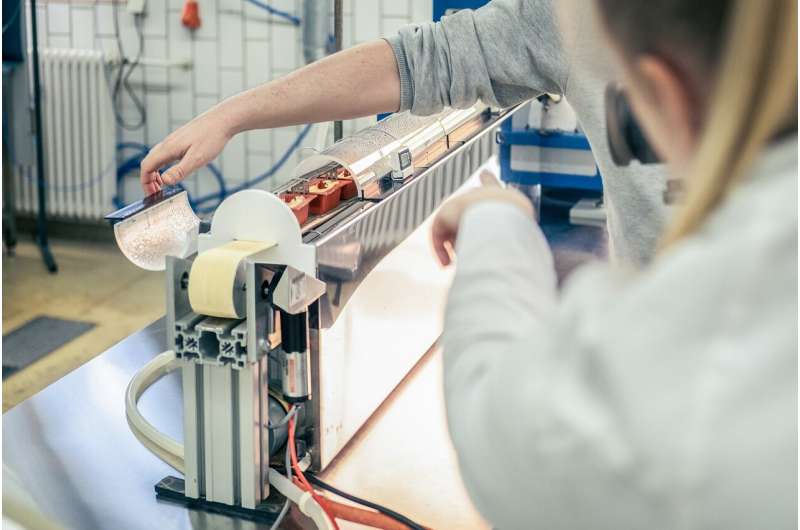

The rolls currently being produced at the Technical Center for Food Science remain small. Natalie Feller’s baked goods are about the size of model train cars and contain 30 grams each. They are placed on the conveyor belt by hand in small silicone box moulds.

Mini-rolls will be steamed for two meters. Two more meters of baking are then done in the continuous oven. The test loaves are golden, steamed and light at the end of this mini-baking line.

Feller is a PhD candidate in the Department of Plant-Based Foods at Hohenheim University. Her objective for the day was to make the fluffiest of breads. She moved from the laboratory to the Technical Center. The University of Hohenheim’s food scientists have a wide range of equipment at their disposal, including that which is used in the dairy industry, bakery trade or butcher shops.

Around 2% to 3 % of the population is affected by gluten.

Feller’s baking experiments combines food technology, materials science, and engineering. This experiment presents a special challenge, since the dough used is gluten-free. It should still produce tasty and fluffy baked goods.

It is due to the fact that gluten is a problem protein for 2% – 3% of people. “We know now three disease patterns related to gluten,” Prof. Dr. Stephan Bischoff of Hohenheim’s Institute of Clinical Nutrition.

Celiac is the most common, which is a combination of allergy and autoimmune disorder. He said that wheat allergy is also widespread, triggered by gluten or similar peptides. There is also a third clinical condition, wheat sensitivity. This has had the least amount of research. It is still not clear what causes wheat sensitivity, and whether gluten plays a part in this case. Our department is therefore tackling this puzzle with great intensity.

Gluten-free food is the only way to treat celiac patients in daily life.

In baked goods that are classic, gluten is used to provide a structural framework.

However, in chemical-physical terminology, gluten is still a major protein. This was confirmed by Prof. Dr. Mario Jekle of the Department of Plant-Based Foods. “Gluten does not just rank as one of the most important proteins in the universe. The food scientist said that it is a great ingredient for baking.

A fully proofed bread dough can be compared to a type of foam which solidifies while baking. This foam is supported by the protein gluten, which gives it structure and helps it not to collapse too early.

It is easy to “lather up” ingredients in gluten-free baking. It is possible to achieve this using the same leavening ingredients as in wheat flour dough, such as yeast, baking soda, or other leavening agent. It has been difficult to maintain the small gas bubbles without the gluten scaffold.

The solution may come from the protein chains of natural proteins

In their current research the food scientists at the University of Hohenheim take a different approach: “Instead of focusing on stabilizing an interface between gas and dough, we focus our attention on alternative proteins that stabilize the interface between the dough and the gas bubbles,” said Professor Dr. Jekle.

The scientists use tailor-made, new proteins to achieve this. Starting materials are peas and rapeseed proteins, which the food scientist then extracts to create the best proteins.

Saponins, which are natural substances, support the new protein substitutes. These are obtained from quinoa seeds—or from, stems, leaves, and flowers of daisies.

Prof. Jekle sees more potential in plant breeding. “If we define requirements precisely, then we can work with the plant breeding to identify new pea types whose proteins are better suited to this approach.”

The second approach adds additional fiber to the diet

Another approach is to use mucins – also known as arabinoxylans – to link proteins, such as rice, maize or oats. The mucilages can be found in the hulls of almost all cereals. They are also used for cattle feed or as bran.

The group led by Prof. Dr. Jekle has found that this approach can be used to add valuable dietary fibers to baked goods. Prof. Dr. Bischoff, a clinical nutritionist at the University of Hohenheim, also emphasizes their importance. “As an example, thirty grams a day of fiber is already good protection against colon carcinoma, one of three cancers that are most common in both men and woman.”

The food scientists at the University of Hohenheim are therefore planning to investigate the use of arabinoxylans in other foods as well—for example, in meat substitutes. This is the exciting part. Not only does the method allow for substitute products to have a meat-like texture, but the dietary fibre also provides them with an additional benefit. There are currently no similar products available on the market.

Bread could be made from 3D printers in the near future

Another vision is to perform the loosening of the dough and the baking process in one step—with the help of 3D printers. This is done by using a nozzle to create the layers of pastry and pores. Over it is a baking unit, which instantly solidifies each layer.

It is thus similar to the process that Salzwedel’s bakers use for their classic Baumkuchen. The dough is again applied in millimeters-thin layers. It is then baked in the traditional way over an open fire. “However our technology at Hohenheim University is much more sophisticated and flexible, allowing us to build many different types of structures,” said Professor Dr. Jekle.

The 3D printer has become a part of his everyday life, and he’s been experimenting with this equipment for years. Whether it’s baked goods, meat, meat substitutes, or side dishes—in principle, almost any food could also be produced from the individual components in a 3D printer, he believes.

The 3D printer is a great addition to the traditional kitchen. It offers two additional advantages: “I can customize meals with printed foods. I can adjust the ratios of carbohydrates, fats, proteins and other ingredients to meet my individual needs.” The 3D food printer can be used to obtain raw materials, such as leftover materials created in the process of producing food.

Provided by

University of Hohenheim

Citation:

The future of gluten-free baking is bright: new proteins will revolutionize the baked goods.

Retrieved on 24 May 2023

from https://phys.org/news/2023-05-delicious-proteins-revolutionize-gluten-free-goods.html

Copyright applies to this document. No fair deal is allowed except for private research or study.

No part of the website may be reproduced or copied without written permission. This content is only provided as information.