Meltio improves the usability of LMD 3D printing with new Horizon software and Laser Calibration System

The 3D Printing Trade Awards 2022 shortlists are actually out there for voting. Who will win the 2022 3DPI Awards? Have your say by casting your vote now.

Metallic 3D printer OEM Meltio has added two new merchandise to its portfolio on the Formnext commerce present: the Meltio Horizon software program and a Laser Calibration System.

Whereas the previous options pre-programmed print and materials profiles, designed to assist customers get their Meltio methods up and operating, the latter can be utilized to simply calibrate these items’ multi-laser deposition heads. Between them, the agency says its newest additions make its machines simpler to make use of, whereas “eliminating the boundaries” stopping steel 3D printing from addressing industrial functions.

“With the launch of our new software program, we facilitate and shorten the training time so that you can democratize steel 3D printing in order that your software program is accessible and simple to make use of for a lot of totally different profiles inside an organization,” mentioned Meltio CEO Ángel Llavero. “The Laser Calibration System will give industrial firms a brand new instrument to have the ability to work with assured reliability within the creation of their steel components.”

Laser Metallic Deposition at Meltio

Based three years in the past as a three way partnership between Sicnova and Additec, Meltio has constructed a enterprise round a wire Laser Metallic Deposition (LMD) know-how. A type of Directed Vitality Deposition (DED), the agency’s course of sees a number of fiber-coupled diode lasers used to soften metals fed out of a central nozzle. As these lasers intersect with alloys, weld beads are shaped, which may be deposited onto a substrate beneath layer-by-layer, as a way of manufacturing fully-dense steel components.

The corporate markets its know-how within the form of the Meltio M450 and Meltio Engine, a toolhead that may be added seamlessly onto CNC machines, robotic arms and gantry methods. Each these perform utilizing a multi-laser deposition head, containing the 1.2kW lasers wanted to show powder or wire feedstocks, together with stainless-steel, titanium, copper and nickel, into advanced components.

Alongside its proprietary 3D printer and LMD 3D printing engine, the agency additionally started promoting wire-based Meltio Supplies earlier this 12 months. The transfer marked a change in route for the corporate, whose providing had historically been open-material. At launch, the vary was marketed as a manner for adopters to attain greater print success charges, whereas making the most of a extra streamlined consumer expertise.

Meltio’s Horizon slicer launch

With its Horizon software program, Meltio has launched a proprietary toolpath generator that may be custom-made to the wants of adopters’ particular person functions. Thus far, customers of the agency’s plug-and-play Meltio M450 3D printer have been compelled to depend on third-party Fused Filament Fabrication (FFF) slicers to arrange toolpaths for prints, however now they’ll entry presets that streamline the entire course of.

Along with conventional slicing parameters like layer top, line width, print pace and assist supplies, Meltio Horizon offers entry to material-specific laser energy, twin wire and sizzling wire settings. Using this performance, customers are capable of create specialised printing profiles, which permit for direct management over the laser and sizzling wire on a ‘per slicing characteristic’ foundation, somewhat than being set for the total half.

This system additionally comes made to measure for Meltio’s wire-laser steel 3D printing course of, in a manner that might present adopters with future value financial savings. Customers are capable of configure their fuel supply and price this straight in Meltio Horizon, with circulate charges being outlined for every materials, whereas its value calculator permits every total challenge to be price-modeled.

At launch, the slicer is just suitable with the M450 system, however Meltio is at present engaged on creating its open software program ecosystem partnerships, in order that it could possibly create 5-Axis G-Codes for CNC and Robotic Integration Meltio Engines.

Handy laser calibration

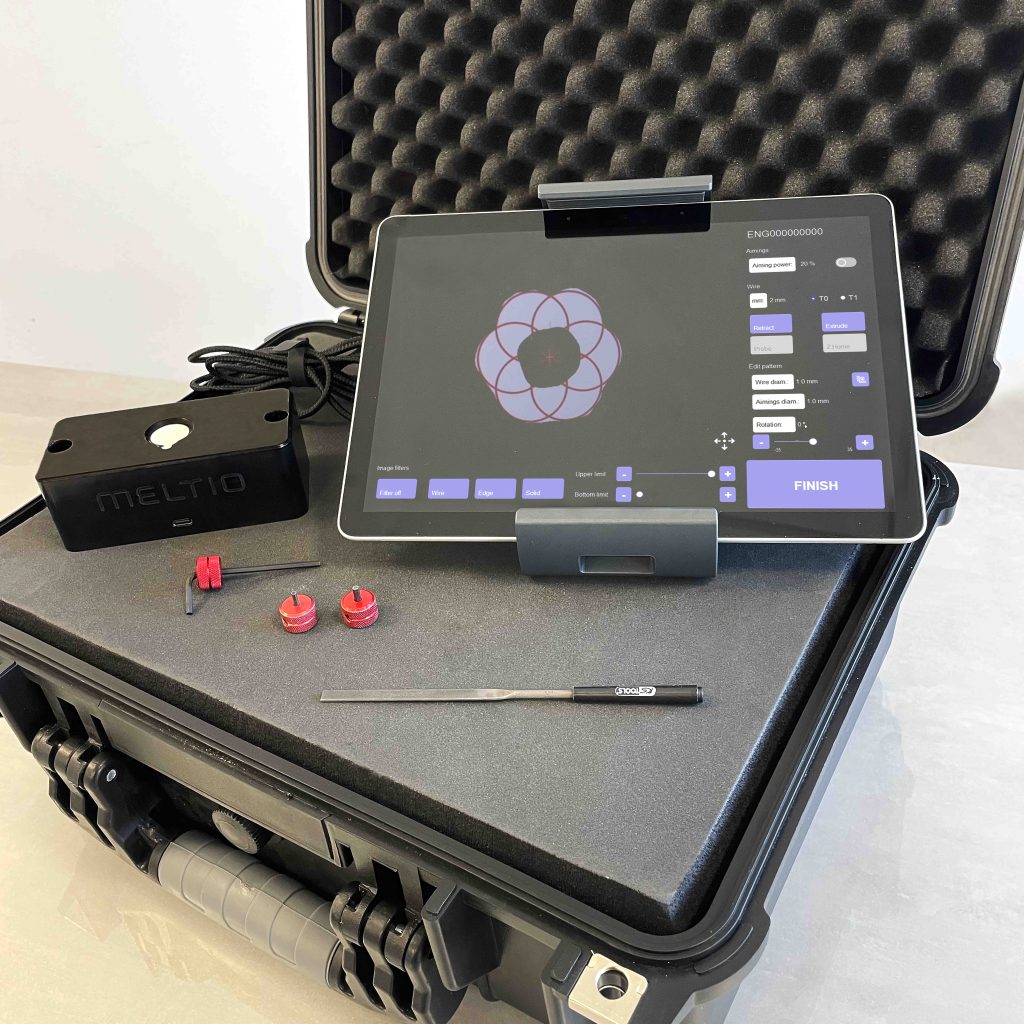

Basically an add-on for calibrating Meltio printheads, the agency’s new Laser Calibration Instrument is designed to make the 3D printing course of extra dependable, and simpler to handle. The system features a laser alignment digital camera that may be positioned beneath machines’ deposition heads, in a manner that gives customers with a transparent view of their lasers’ focus factors.

Shipped with a conveyable controller and software program designed to filter ensuing photos, this package is claimed to information customers’ efforts to focus every laser on probably the most optimum level. In comparison with difficult guide calibration methods, Meltio says its new package deal makes it a lot simpler to make sure that lasers are correctly aligned, and keep away from points like power inefficiency or defects.

The entire alignment course of is quick as effectively, with the corporate boasting that it’s twice as fast to hold out as guide options, and as soon as full, it’s mentioned to boost Meltio 3D printing repeatability and traceability. Not like with its Horizon software program, the calibration instrument can be suitable with Meltio’s M450 printer and CNC and Robotic Integration Engines, making it out there to the agency’s total consumer base.

Take a look at our full Formnext information round-up for the newest from 3D printing’s main commerce present.

To remain updated with the newest 3D printing information, don’t neglect to subscribe to the 3D Printing Trade e-newsletter or observe us on Twitter or liking our web page on Fb.

When you’re right here, why not subscribe to our Youtube channel? that includes dialogue, debriefs, video shorts and webinar replays.

Are you in search of a job within the additive manufacturing business? Go to 3D Printing Jobs for a choice of roles within the business.

Featured picture reveals the Meltio Laser Calibration System. Picture by way of Meltio.