Max Planck and Heidelberg researchers explore touchless 3D printing using acoustic holograms

Researchers at the Max Planck Institute for Medical Research and Heidelberg University have been investigating the “touchless 3D printing” concept to improve precision and 3D printing speed.

The journal of Advanced Sciences published the new study. Multiple acoustic holoscops are used to create pressure fields which can be used to print solid particles, gel beads and living cells. The researchers are hoping to create new opportunities in biomedicine and other fields where it is possible to create complex and precise structures.

With ultrasound holograms, you can create 3D shapes

The study’s lead author, Kai Melde, highlights the potential of ultrasound-based 3D printing technology for assembling biological cells, as it is gentle and non-toxic to cells. Non-contact remote assembly helps to maintain sterility which can help keep cells healthy.

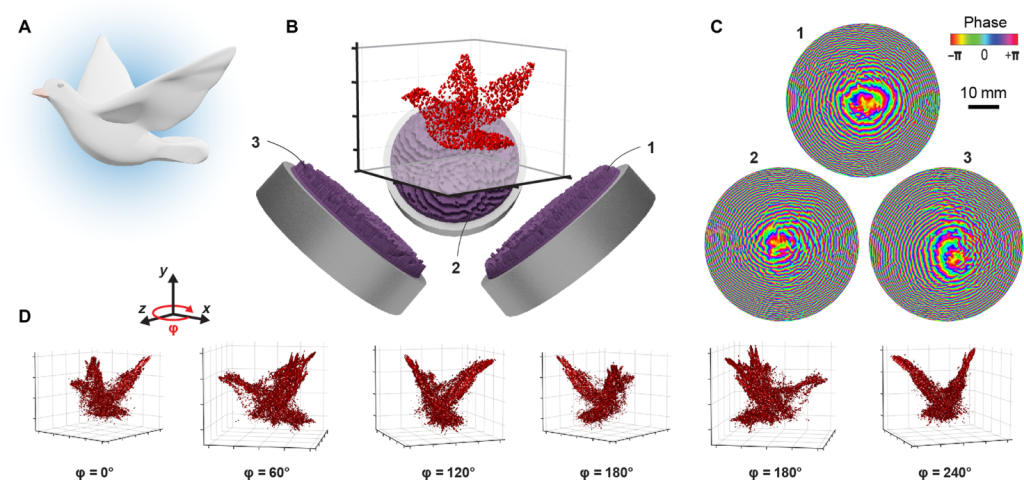

The research introduces a novel method of creating precise 3D shapes through the use of multiple “acoustic holograms,” which resemble sound blueprints. This method allowed the team to create precise 3D shapes by using small particles and cells faster than traditional 3D printers. This technology is compatible with many materials and can be used for medical purposes, including drug delivery and tissue engineering.

Melde stated that 3D shapes using sound waves require complex algorithms and multiple holographic field interactions. This presents a problem in terms of computational power, as memory requirements for 3D shapes increase with each dimension. The wavefield must be calculated for the entire volume. Heiner Kremer is a member the team who wrote the required computer programs. He says digitizing 3D objects in ultrasound hologram field fields takes a lot more computing power so it was necessary for a new way to compute. To overcome this challenge, the researchers used GPU acceleration and Google’s TensorFlow software.

Despite the technology’s limitations, such as being constrained by the power of sound waves and requiring materials that can resist gravity, the new 3D printing method represents a “promising step forward” in the field of sound wave-based 3D fabrication.

Was 3D printing possible before the advent of ultrasound?

Researchers at Universiti Teknikal Malaysia Melaka (UTeM), have developed a 3D printing machine that can produce more resilient parts from ABS. Two piezoelectric transducers were attached to a standard Fused Filament Fabrication (3D printer) to strengthen recycled ABS. After granulating ABS and extruding into a 1.75 mm-thick filament, the UTeM experiment began 3D printing samples. The prototype FFF machine was equipped with a piezoelectric sensor to improve its stability via ultrasound vibration. Even though the first models made with a nozzle temperature of 230°C had surface flaws, the engineers found that raising this parameter to 270°C and slowing down the print speed fixed these problems. Researchers also found that making parts vibrate at 20 kHz with ultrasound “significantly improved recycled layer adhesion.”

Concordia University researchers have created a novel method for direct sound printing (DSP). This uses ultrasound waves to create precise and intricate objects. In a published paper, they explain how sound waves can be used to produce sonochemical reaction in small cavities. This creates intricate geometries which cannot be achieved with current methods.

“Ultrasonic frequencies are already being used in destructive procedures like laser ablation of tissues and tumors,” said Muthukumaran Packirisamy, a professor in Concordia’s Department of Mechanical, Industrial, and Aerospace Engineering. “We wanted to use them to create something.”

What is the? Future of 3D printing For the next ten year, what will it be?

What engineering challenges In the next decade, will the challenges of additive manufacturing be addressed?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry NewsletterFollow us on TwitterYou can also like our page Facebook.

While you’re here, why not subscribe to our YouTube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking to find a job in additive manufacturing? Visit 3D Printing Jobs Here are some examples of the roles available in this industry.

The featured image illustrates the concept of creating compact 3D pressure images using acoustic sound waves. Max Planck Institute for Medical Research.