3D printing with bacteria-loaded ink produces bone-like composites

EPFL researchers published a method of 3D printing an ink that is calcium carbonate-producing bacteria. The 3D printed mineralized bio-composite, which is made from minerals, is extremely strong and light. It can also be used for biomedicine.

Nature has an extraordinary knack for producing composite materials that are simultaneously light and strong, porous and rigid—like mollusk shells or bone. But producing such materials in a lab or factory—particularly using environmentally friendly materials and processes—is extremely challenging.

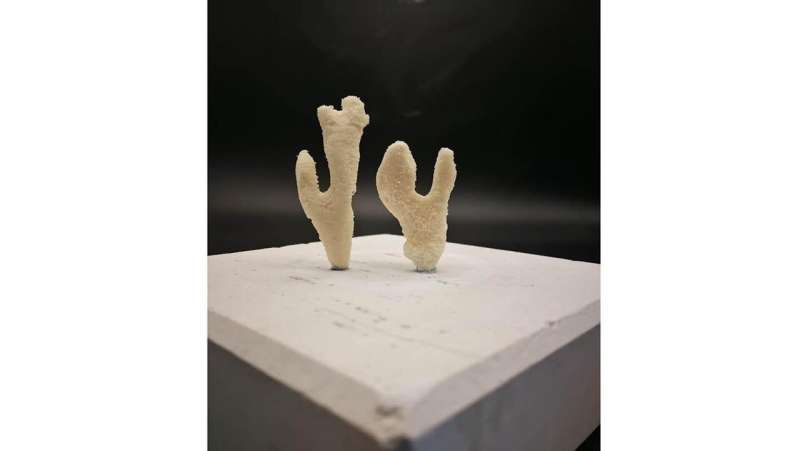

The School of Engineering’s Soft Materials Laboratory turned to nature as a source of inspiration for their solution. The 3D printed ink they developed contains Sporosarcina pasteurii, a bacteria that triggers mineralization that results in calcium carbonate (CaCO) when it is exposed to a solution containing urea.3). The upshot is that the researchers can use their ink—dubbed BactoInk—to 3D-print virtually any shape, which will then gradually mineralize over the course of a few days.

“3D printing has become more important in general, but there are a limited number of materials that can 3D-print because inks must meet certain flow conditions,” says Esther Amstad (lab head). “For example, they must behave like a solid when at rest, but still be extrudable through a 3D printing nozzle—sort of like ketchup.”

Amstad explained that while 3D printing inks that contain small minerals particles were used previously to meet certain flow criteria, the resulting structures are soft or shrink upon drying. This can lead to cracking and loss control over the final product’s shape.

“So, instead of printing minerals, our BactoInk printed a polymeric scaffold, which was then mineralized in a separate step. The scaffold bacteria triggers the mineralization process, which takes around four days. The final product will have a mineral-content of more than 90%.

The end result is a bio-composite with a high level of strength and resilience. This can be manufactured using a standard 3D printing machine and natural materials without the need to heat up as often required for making ceramics. Because the final product is not made from living bacteria, it has been submerged in ethanol after the mineralization process.

This method describes the first 3D printing ink to use bacteria to induce mineralization. It was published in the journal Materials Today.

Art, coral reefs and bone patching

Soft Materials Lab’s approach could be applied in many areas, including ecology and art. Amstad believes that the restoration of artworks could be greatly facilitated by BactoInk, which can also be directly injected into a mold or target site—a crack in a vase or a chip in a statue, for example. Because of its mechanical properties, the ink is able to resist shrinkage and withstand further damage.

It uses only eco-friendly materials and can produce a mineralized biocomposite. This makes it a promising candidate to build artificial corals that can be used to regenerate marine reefs. The biocomposite’s mechanical and structural properties are similar to bone, which could make it attractive for biomedical applications in the future.

Amstad states that the versatility of BactoInk’s processing and the excellent mechanical properties of mineralized materials open up new opportunities for fabricating lightweight, load bearing composites that are closer to natural materials than synthetic ones.

For more information, click here

Matteo Hirsch et al, 3D printing of living structural biocomposites, Materials Today (2023). DOI: 10.1016/j.mattod.2023.02.001

Ecole Polytechnique Federale de Lausanne

Citation:

3D printing using bacteria-loaded ink creates bone-like composites (2023 and 23 February)

Retrieved 23 February 2023

from https://techxplore.com/news/2023-02-3d-bacteria-loaded-ink-bone-like-composites.html

Copyright is reserved for this document. This document is not intended to be used for research or private study.

Without permission, part of the content may be reproduced. The information is provided only for informational purposes.